Heat recovery technology

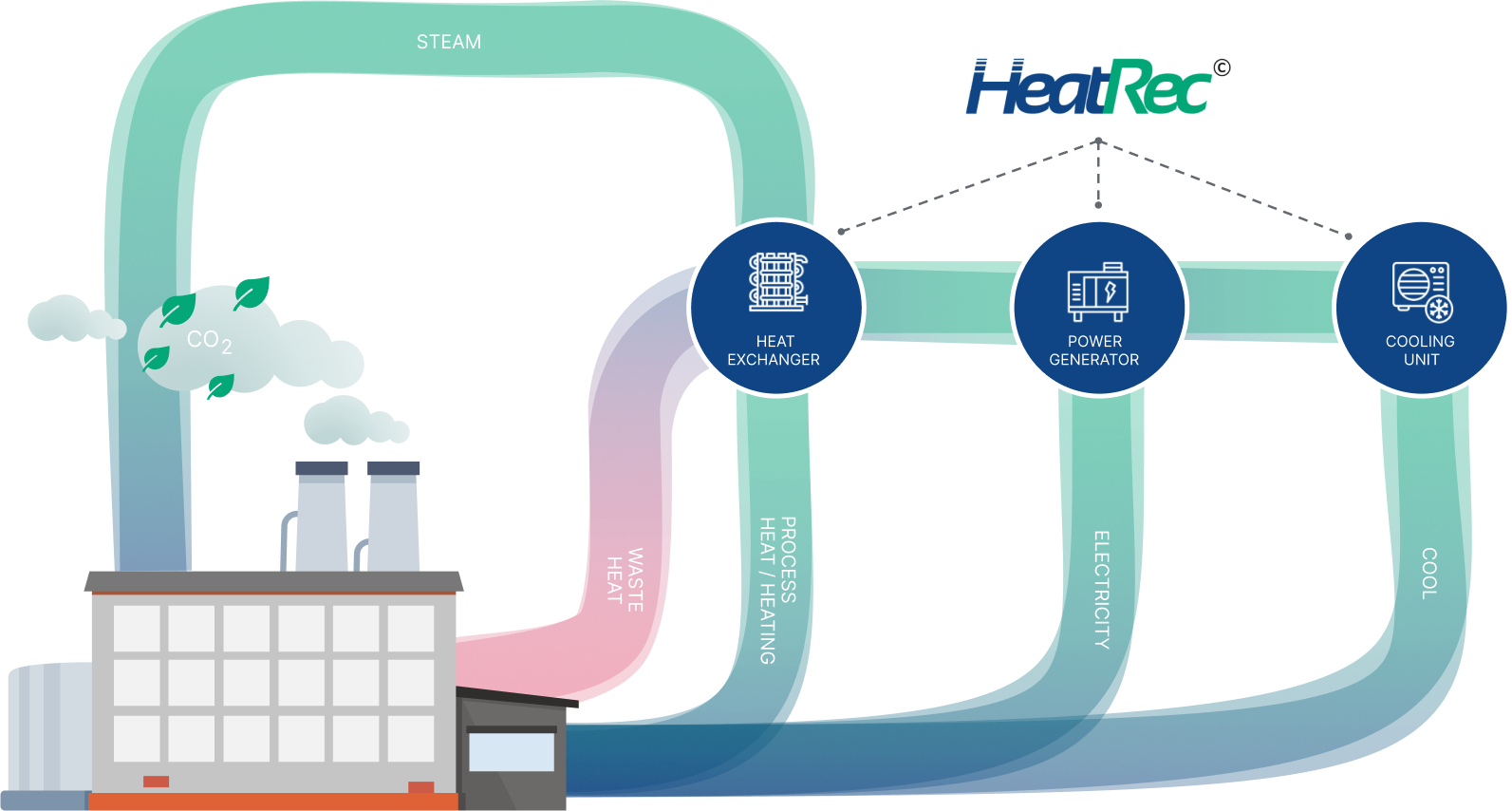

Almost every industrial plant generates waste heat in its production processes. Our HeatRec© industrial heat recovery systems enable you to manage wasted energy and use it according to your plant’s needs, while reducing CO2 emissions and lowering production costs.

HEAT/HEATING/DOMESTIC HOT WATER (DHW)

The most efficient way to manage waste heat is to reuse it in a process – to heat process gases or water, material, or in the drying process – thus reducing the need for externally supplied energy.

HeatRec© systems are also capable of using waste heat to heat domestic hot water or as a source of heating for your plant or surrounding infrastructure, including district heating networks.

ELECTRICITY

HeatRec© systems, through the use of modern and proven organic rankine cycle (ORC) modules, can be used to produce electricity to be employed in your facility. Unlike PV sources, these types of installations provide a stable source of cheap electricity, independent of the time of day or weather conditions.

COOL

Thanks to the use of special chillers, HeatRec© installations are able to generate cooling from recovered waste heat – whether you have a need to cool social areas, production halls or use the cold for process purposes.

Waste heat sources

We often do not realise how much of the equipment and installations in our production facility are sources of usable waste heat. Our experts can help identify such sources at your site.

Furnaces

Turbines and engines

Refrigeration equipment

Compressors

Chimneys

Server rooms

Dryers

Other equipment

Furnaces

We offer waste heat recovery from furnaces and heating equipment, usually by using flue gas heat or modifying existing cooling and ventilation systems. To find out more, contact us!

Request a contactTurbines and engines

Turbines and engines generate large volumes of heat during operation, which is then dissipated and the energy contained is most often lost irretrievably. HeatRec© systems allow this energy to be reused. To find out more, contact us!

Request a contactCompressors

Modern compressors are usually designed to recover the heat generated during their operation. Our HeatRec© systems will enable you to use this free energy at your facility. To find out more, contact us!

Request a contactChimneys

Hot air, steam or flue gas is a very good source of energy for reuse thanks to our HeatRec© heat recovery systems. To find out more, contact us!

Request a contactServer rooms

Large server rooms or data centres generate enormous amounts of heat, which is usually released into the atmosphere and irretrievably lost. Our HeatRec© systems will enable you to reduce your energy costs using this heat. To find out more, contact us!

Request a contactDryers

Depending on the technology applied, our HeatRec© systems make it possible to increase the efficiency and lower the costs of the drying process by recuperating the recovered heat or using it elsewhere in your facility. To find out more, contact us!

Request a contactIs it worth it?

In an era of rising gas and energy costs and increasing environmental concerns, recovering energy from waste heat is one of the most obvious and effective methods of achieving the stated goals of cost and CO2 reduction.

Request an expert talkHeatRec© waste heat recovery plants are a stable source of low-cost and green energy. We will effectively reduce your costs for electricity, natural gas or other heating fuels. In addition to the savings resulting from lower consumption, it is noteworthy that reduction of fixed costs, such as ordered power charges is also possible. Our systems do not adversely affect existing technology and infrastructure and do not require additional utilities, ongoing maintenance or frequent servicing – operating expenses (OPEX) are kept to a minimum.

Reusing heat that is currently wasted at your site can significantly increase the efficiency of energy-intensive production processes. Particularly when the recovered heat can be reused directly in the process – for instance by heating the furnace charge, air or process gases.

Our HeatRec© systems make enable reduction of your plant’s demand for electricity, thermal energy, steam, domestic and process hot water or cooling. Our customers also become independent of external suppliers of these utilities, which affects the security of their production and increases the certainty of continuity of supply.

Waste heat is treated as a renewable energy source (RES). It is also believed that due to increasing environmental restrictions and requirements, it should form a noticeable part of the energy mixture in developed economies in the coming years. Every 1 MWh of electricity generated from recovered waste heat represents approximately 650 kg of CO2 emission reduction. Even higher efficiencies can be achieved by reusing waste heat directly in the process or for heating purposes. We are proud of the positive impact of HeatRec© systems on the environment and the reduction of human-induced climate change.

HeatRec© waste heat recovery systems result in an increase in the energy efficiency of your facilities, with an option of obtaining so-called white certificates (energy efficiency certificates) on the investment completion. The white certificates obtained are tradable – they can be sold, thus improving the economic figures of the investment. Click for more details.

The use of HeatRec© heat recovery systems provides a positive effect on reducing the rate of wear and tear on the equipment and machinery that emit it, as well as on the associated facilities and installations (chimneys, filters, ventilation, steelwork, pipework, measuring equipment, etc.). Managing heat also means reducing its uncontrolled and unlabelled emissions, which significantly improves safety at your facility.

What do we offer?

Our comprehensive range of HeatRec© systems covers all stages of your investment – support from the waste heat source identification process, through design and construction, to after-sales support and service. We operate throughout Poland and Western Europe.

Feasibility study

We have the expertise and experience to offer you technically optimal and feasible solutions for waste heat recovery. As part of our offering, we review various options and provide our recommendations, supplemented by technical and economic analysis.

Energy audit

On request, we provide energy audits – before and after the investment completion. Specific and comprehensive information on heat recovery parameters that can be used are provided to you. For example, to obtain white certificates or to report on the CO2 reduction targets.

Cost-effectiveness calculation

We produce our analyses and recommendations based on the economic justification for the investment. We will provide you with a full financial model including the expected waste heat recovery parameters and the resulting financial benefits. We will calculate the payback period for you, carry out a sensitivity analysis and a full evaluation of the investment – including capital expenditure and operating costs.

Funding

We support our clients in obtaining investment funding. Using our expertise in dealing with financing institutions, we are able to assist you in obtaining optimum financing, also using the support instruments available from state institutions.

We obtain so-called white certificates (energy efficiency certificates) for our systems, which improve the economic performance of the investment and reduce CAPEX.

Comprehensive service

We support you at all stages of your investment: from concept, building design with the necessary decisions to detailed design, equipment selection, procurement, implementation and commissioning of the waste heat recovery plant. This keeps the effort and involvement on your side to a minimum.

Investor supervision

If you decide to build the heat recovery system yourself based on our design, we can provide a project supervision service on your behalf.

Service

As part of the HeatRec© offering, we also offer you a high quality service during the warranty period and subsequent years of the system’s life. Our service operates throughout Poland and Western Europe.

How we act?

Based on many years’ experience of working with clients in industry, we propose a course of action that guarantees the effective implementation of our projects.

Customer contact and site visit

In the first instance, we will provide you with a detailed introduction to our range of products, get to know your needs and discuss potential heat recovery options for your facility. We will also offer to sign a non-disclosure agreement.

Completion of basic documentation

We will ask you to provide us with basic data and documentation on the selected systems and facilities. Their analysis will enable us to prepare proposals for further action. Optionally, we will make a 3D scan of the parts of your plant of interest.

Development of a preliminary concept – FREE OF CHARGE!

On the basis of the information obtained and its analysis, we will present you with a preliminary variant concept of our systems along with a technical assessment of the heat recovery potential. Preparation of the initial concept takes approximately one month.

Simplified Feasibility Study

At this stage, we will carry out a Simplified Feasibility Study for you, detailing the initial concept, further extended by a cost estimate and calculation of the benefits of the investment. Once you have accepted our concept, we will provide a full quotation for the HeatRec© heat recovery system. Turnaround time – approx. 2 months.

Decision and signing of a contract

We are flexible and adapt the form of our cooperation to your needs. We propose to carry out the project in any formula of your choice – E (design only), EPC (turnkey construction) or EPCM (as contract engineer).

Project development

At this stage, we will design the system including the definition of binding heat recovery parameters. We will select the plant equipment and accessories. We will obtain planning permission and arrange all the necessary paperwork for the start of construction and installation work. We will also carry out an energy audit at your request. Turnaround time – approx. 4 to 6 months.

Investment implementation

We carry out heat recovery systems in a comprehensive manner – we have our own construction resources and the equipment necessary to carry out even the most elaborate systems. In addition to the heat recovery installation itself, we also carry out building, construction, assembly and electrical and automation work. Turnaround time – approx. 4 to 12 months.

Commissioning, measurements and final report

Once the investment part has been completed and the system is up and running, we will provide full documentation and carry out training for your crew on how to operate it. At your request, we will carry out an as-built energy audit and measure the achieved heat recovery parameters.

Who we are?

HeatRec© waste heat recovery systems are part of Mostostal Zabrze Biprohut S.A. wide offer. – a modern engineering office, part of the Mostostal Zabrze Group, listed on the Warsaw Stock Exchange.

Our company specialises in providing comprehensive technical, legal and economic advice and engineering services at various stages of a project, both pre-design and implementation. The company’s offer includes not only support in the development of concepts, studies and analyses, but also environmental applications, construction projects and designs necessary for obtaining a building permit, as well as multi-discipline detailed and workshop designs. In addition, we provide original supervision and full management services for investment tasks.

We encourage you to take a look at our full offer at http://www.biprohut.mz.pl/en/

Any questions?

We will contact you

We encourage you to complete the form below and contact our experts. Once we have received your enquiry, we will contact you within 2 working days.